During Kilele cha Wiki ya Maji 2025, Kilitek Africa hosted one of the busiest booths at the exhibition — not because of flashy hardware alone, but because visitors arrived with real water problems they needed solved.

Plant managers, facility engineers, hotel owners, and municipal officers came in with the same recurring story: scaling heat exchangers, cloudy tap water, brown hotel linens, customer complaints, and regulatory pressure they could no longer ignore.

Listening Before Prescribing: The Kilitek Approach

From the first hour of the exhibition, the Kilitek team made a deliberate choice: listen first, prescribe later. Rather than pushing standard equipment packages, engineers spent time understanding:

- Where the water was coming from — borehole, municipal, or surface source

- How it was being used — boilers, cooling towers, bottling lines, hotel guest floors, or dialysis units

- What was actually going wrong — scale, corrosion, biological growth, staining, odour, or pressure loss

- What regulations or internal standards the client had to meet — NEMC limits, WHO guidelines, brand audits, or export requirements

That consultative posture turned the booth into a mini design office. Whiteboards filled up with sketches of existing systems, problem areas were circled, and operating data like flow rates and operating hours were written down so nothing was left to guesswork.

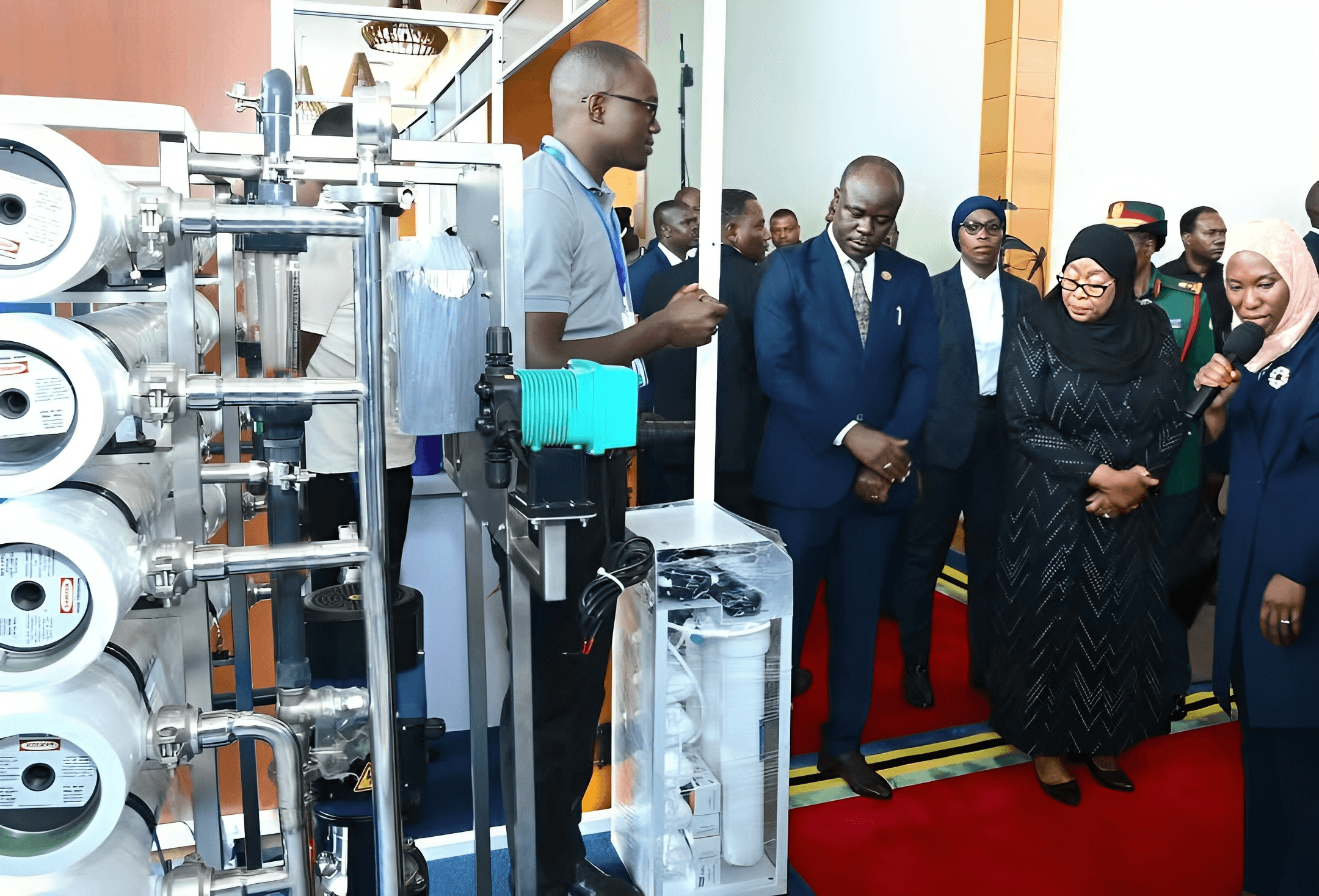

Hardware as a Backdrop, Not the Main Character

The booth itself showcased a range of industrial and commercial water treatment systems — compact RO skids, softening units, filtration trains, and chemical dosing systems.

But in every photograph from the event, the pattern is the same: the equipment sits in the background while engineers and visitors stand at the foreground, deep in conversation. The real product on display was clarity.

One photo from the booth — now part of our event gallery — captures this perfectly: a Kilitek engineer leaning over a table, marker in hand, mapping a client’s high-level water “headache” into a concrete treatment train with clear stages and measurable outcomes.

.jpeg)

.jpeg)

From Vague Symptoms to Clear Treatment Trains

Most visitors didn’t arrive asking for “a 5 m³/h RO skid with duplex softeners and antiscalant dosing”. They arrived with symptoms:

- “Our kettles, boilers, and showerheads keep scaling every few months.”

- “Customers complain that the hotel water stains towels and has an odour.”

- “We keep failing discharge tests and don’t know which parameter is the real problem.”

- “Our bottled water line keeps stopping because of filter blockages.”

At the booth, these symptoms were translated into structured treatment plans:

- Scaling and hardness issues → Properly sized softening systems with resin selection, brine tank design, and regeneration logic tuned to the client’s load.

- Colour, odour, and turbidity complaints → Multi-stage filtration and activated carbon polishing, paired with disinfection.

- Quality and compliance failures → Engineered RO skids and dosing systems with online monitoring points for conductivity, pH, and residuals.

- Frequent filter blockages and production stops → Redesign of pre-treatment trains, settling and multimedia filtration ahead of polishing stages.

A Human, Consultative Booth Experience

What stood out to many visitors was that the booth didn’t feel like a shop — it felt like a clinic for water systems. Engineers asked diagnostic questions, used photos and plant P&IDs visitors brought with them, and then explained options in plain language.

Instead of pushing catalog items, the Kilitek team:

- Sketched before-and-after process diagrams right at the table.

- Explained how CAPEX and OPEX would change with each option.

- Highlighted what could be reused from existing infrastructure.

- Identified quick wins (like dosing adjustments) and long-term upgrades.

.jpeg)

Why Events Like Wiki ya Maji Matter

Kilele cha Wiki ya Maji isn’t just a calendar event — it’s a pressure release valve for operators who live with water problems every day. In one place, they can compare technologies, talk to engineers, and test whether a vendor truly understands their context.

For Kilitek, the exhibition is a chance to demonstrate what makes our approach different:

- Local context: Deep understanding of Tanzanian raw water realities and regulations.

- End-to-end thinking: From raw water intake, through treatment, to wastewater and reuse.

- Lifecycle support: Design, build, chemicals, spares, and 24/7 after-sales service.

From Conversations to Long-Term Partnerships

Many of the conversations that started at that booth didn’t end when the exhibition closed. Site visits were scheduled, water analyses were commissioned, and formal proposals were prepared.

For some visitors, the biggest win was not signing a purchase order on the spot — it was finally having a clear roadmap:

- Audit current water use and quality.

- Prioritize risks: scaling, quality, compliance, and cost.

- Match each pain point to a specific treatment stage.

- Phase implementation to match budget and downtime windows.

That’s the story this photo set tells: not just equipment on display, but human, consultative engineering in action — turning vague water headaches into tailored, long-term treatment plans that fit each client’s reality.

Thinking about your own plant or facility? Bring your water analysis, a rough process diagram, or even just your biggest complaints. Like at Wiki ya Maji, we’ll start with listening — and end with a plan.

Kilitek Team

Expert insights on water treatment solutions, industry best practices, and sustainable water management across East Africa.

View All Articles